Description

Continuous and precise level measurement in unpressurised, open basins and tanks as well as underground applications such as shafts, wells and boreholes.

Technical Data

Properties

- Protection class EN60529

- IP68

- Operating temperature

- -10...70 °C (PVC: -10...60 °C)

- Storage temperature

- -25...70 °C (PVC: -10...60 °C)

- Power supply

- 15...30 V DC

- power

- max. 25 mA

- Output

- 2-Leiter-Technik

- Measuring range

- 0,8...10 mWs (Standard)

- Overpressure

- abhängig vom Messbereich

- Deviation from characteristic curve

- Nichtlinearität,

- Insulation resistance

- > 100 kΩ

- Short-circuit resistance

- permanent

- Reverse polarity protection

- keine Schädigung o. Funktion bei vertauschten Anschlüssen

Materials

- Housing

- Edelstahl 1.4571, PVC, PVDF

- Measuring cell

- Edelstahl 1.4404, Keramik Al2o3 96%, Keramik Al2o3 99,9%

- Seals

- FKM (Viton ®), EPDM, FFKM (Kalrez ®)

- Cable

- PVC, PUR, FEP (Ø8 mm; 2 x 0,25 mm2 mit Luftschlauch und PTFE-Filter

HD-100 | HD-102 | HD-104 application-specific configuration

HD10 - [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ] - [ 5 ] - [ 6 ] - [ 7 ]

Further product information

Hydrostatic probes (level probes) are based on a pressure measurement in a stationary liquid that is subject to a homogeneous gravitational field. This pressure is referred to as hydrostatic pressure. The hydrostatic pressure in a liquid increases in proportion to the filling level. This means that the higher the column of liquid, the higher the pressure at the bottom of a tank, for example.

Due to the measuring principle, hydrostatic probes enable continuous and precise level measurement in unpressurised, open basins and containers as well as underground applications such as shafts, wells and boreholes. Depending on their design, the Fluid.iO HD probes type HD-1XX are suitable for use in water, clean to slightly contaminated liquids, acids, alkalis and aggressive media.

Depending on the access option, the level is recorded via immersion or screw-in probes. The hydrostatic pressure of the medium acts on the pressure measuring cell of the probe and is converted directly into an electronic standard signal to display the level in analogue form, e.g. in m, % or litres.

Advantages of Fluid.iO hydrostatic probes

| Precise & reliable | Versatile | Simple device design |

|

|

|

Function and measuring principle

The Fluid.iO HD probes measure the hydrostatic pressure. If the fill level is identical, the hydrostatic pressure in all containers is the same regardless of the design (hydrostatic paradox).

In open containers, the pressure in the liquid is made up of the weight-related pressure due to the liquid column and the air pressure (atmospheric pressure) above the liquid level. In the hydrostatic probes, there is a pressure measuring cell at the lower end of the probe, with which the difference between the two pressures is recorded. This compensates for possible changes in air pressure due to changing weather conditions or different measuring locations. The pressure acting on the pressure measuring cell is converted into a corresponding output signal via integrated evaluation electronics.

P = ρ * g * h | P = pressure | ρ = density of the liquid | g = acceleration due to gravity | h = depth

The output signal of the HP probe can be converted into a level height. It should be noted that the hydrostatic pressure depends on the density of the liquid. A liquid with a higher density, such as water, exerts more pressure on the ground than a liquid with the same volume but lower density, such as oil.

Design variants

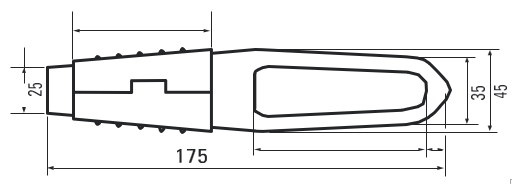

The hydrostatic probes are available as immersion probes for suspended installation from above and as screw-in probes for installation in the tank wall. To ensure the best possible resistance, the hydrostatic probes can be constructed with different materials for the housing, measuring diaphragm, seals and cable. For product-specific configurations, please refer to the type code in the corresponding data sheet.

product line |

||||||

| Hydrostatic probes |

HD-100

|

HD-102

|

HD-104

|

HD-110

|

HD-112

|

HD-114

|

| Product or catalogue number | D-02-01-01 | D-02-01-02 | ||||

Design |

||||||

|

Product type 0 = immersion probe |

0 | 0 | 0 | 1 | 1 | 1 |

|

Housing Material 0 = stainless steel |

0 | 2 | 4 | 0 | 2 | 4 |

Material measuring cell |

||||||

| stainless steel 1.4404 | ✔ | ✔ | ||||

| Ceramics AI 203 96 % | ✔ | ✔ | ✔ | ✔ | ||

| Ceramics AI 203 99,9% | ✔ | ✔ | ✔ | ✔ | ||

Material seal |

||||||

| Viton | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| EPDM | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Kalrez | ✔ | ✔ | ✔ | ✔ | ||

Electrical connection |

||||||

| PVC-cable | ✔ | ✔ | ✔ | |||

| PUR-cable | ✔ | ✔ | ✔ | |||

| FEP-cable | ✔ | ✔ | ✔ | |||

| Plug Form A | ✔ | ✔ | ✔ | |||

Connection thread |

||||||

| G 3/4" | ✔ | |||||

| G 1 1/2" | ✔ | ✔ | ||||

System extensions

The HP probes can be supplemented with additional display and evaluation devices to display the fill level and for additional limit value monitoring and simple control of pumps, etc:

- Luminous Row Display Type TK-320 or TK-321 …

- TK-313 and TK-315 …

- Easily programmable digital displays of the type AD-310 or AD-313

Structure of the measuring system

The HD-1xx series measuring system consists of a hydrostatic immersion or screw-in probe and an analyser or digital display.

The programmable digital display AD-313 intended for panel mounting enables individual output variables (litres etc.) to be displayed as variables describing the fill level using the scaling function. Adjustable limit values can also be monitored by means of an alarm function as a relay output.

The TK-313 and TK-315 analysers are compact versions for top hat rail mounting. Here the fill level is displayed in %. Furthermore, 2 limit values can be monitored with the TK-313 and four limit values with the TK-315 via relay output.

Electrical connection

The hydrostatic probes provide the measured value for the fill level as a 4...20 mA current signal in a 2-wire version.

|

Mounting accessories

Mounting accessories include a connection box with pressure equalisation element as well as stainless steel, PVC, PVDF screw fittings, tension clamps and a flange on request.